The printing of packaging is a long and difficult subject, so if you intend to start a new business, the choice of packaging can become a real headache to choose all the details. But when it comes to type of prints, which should you use? We will help you differentiate which ones, with pros and cons, are the best types of printing for your packaging.

Offset

Offset is a type of printing that derives from lithography, and uses CMYK printing (with 4 inks). Its operation goes in this order: a laser engraves on a plate, usually made of rubber, the design that we want to print, so that ink is applied to the marked plate. Then, the material goes through marked rollers, where the impression is captured. It makes the impression very clear and of high quality because we don’t print directly on the paper, it is the rubber that receives the first ink. Therefore, the pores absorb the excess ink and are not captured in the material.

Not all printers can use this technique, since they need special plates to carry the material wich are very expensive. Also, work can’t be manipulated until after 24 hours. We recommend this type of printing when you use them as a sales box, with exclusive and limited edition intention.

Flexography

Also known as “Flexo”, works perfectly with flexible packagings and on corrugated cardboard. As a positive part, this type of printing has a low cost per unit, in addition, the material needed for printing are also cheap. Also, aqueous and oily inks can be used.

It has some negative points: it has worse print quality than lithography, and using soft colors (or in 4-color processes) we can have some problems. The colors in flexography are limited (although it has a catalog with several references) but when “mixing” with the surface of the cardboard, it does not usually have a very vibrant result.

This type of printing is recommended when you are going to make shipping boxes with printed backgrounds or with startling logos.

Digital

Also known as “Ink Jet”, this type of printing is often used in labels, prototypes or boxes with corrugated cardboard, as well as flexible packagings. The advantages of this technique are the following: it has no cost when assembling special modules and printing is relatively fast. Thats why low minimum orders can be profitable, but they will have lower quality compared to lithography.

However, as a negative point, making large volume of orders is expensive since the cost per unit is higher, therefore you might use it if you need boxes in small quantities.

Rotogravure

Also known as “gravure”, this type of printing goes along with flexible packaging and laminated cartons. Its print quality is very high, so you can print images and add PMS colors in a similar way to lithography. Also, you can’t lose quality even if large quantities of product are printed.

The downside is that there are not many materials which you can print on with this technique, plus you need a large investment in machinery. To take advantage of rotogravure it is necessary to print large volumes, although it also has a long printing time.

Serigraphy

Screen printing suits very well on any type of support. This technique is mainly used on prefabricated packaging, such as bottles, cups or T-shirts since it does not need large volumes to be profitable. Furthermore, it’s not limited to a flat surface, it can be printed with volume and objects.

It has its unfavorable points too: Its production is usually slower than lithography. You can’t print images with high quality, so it will not look quite good if you put a picture or an image with CYMK.

This type of printing is recommended for non-photographic prints, and is also better for single-ink prints.

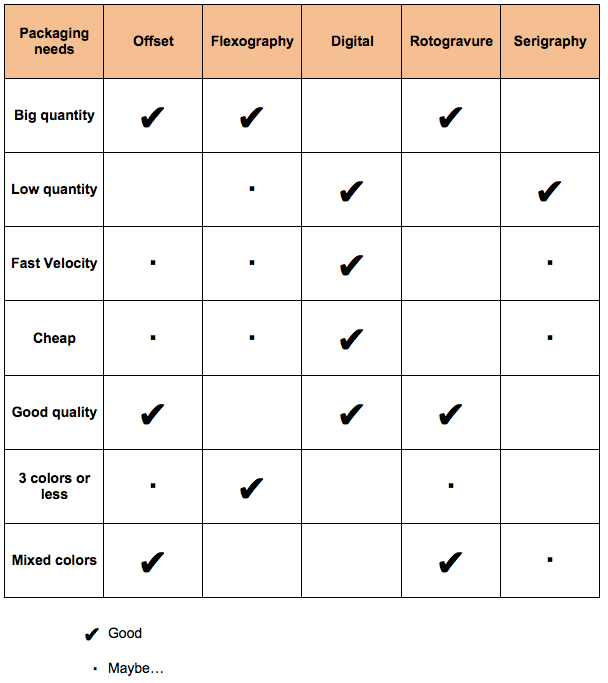

Here you have a table that will help you get oriented with everything we have explained. Now you just have to see what is your ideal packaging and apply the printing technique that best suits you.