Have you ever printed some design and the color looked different from the computer? This is due to the incorrect use of color sample. Therefore, when you start the design it’s important to select which color model you are going to use. We discard RGB and HEX, which are only used on the screen because they are generated with light, so we will always have to use Pantone or CMYK, because they are special for ink.

Choosing the color according to the screen

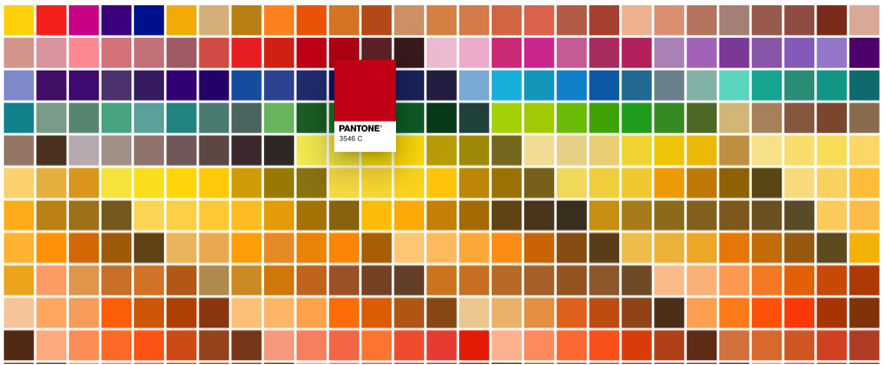

If you often do design projects, it’s essential to have your own pantoneras, so you can print with the color you truly want. It’s very simple: choose the color, look at the code and then look for it in the program you are using.

However, you can also do it in reverse: match the colors of the screen with the Pantone. Just choose the color in the screen and then look in the pantonera what color is. It’s possible that the number of the screen color and pantonera do not match. This is because each computer calibrates the color slightly differently in RGB, although for production is exactly the same.

What are you going to print on?

There are two essential versions of Pantone:

-plasticized (coated)

-non-coated plasticized (offset)

It is important to keep this in mind: It’s not the same to print on paper porous (offset), where you lose some vitality and shows a more matte finish, than on a coated material, where it will be more vibrant and bright. That’s why it’s important to know about what type of material is printed. Look in the pantonera the color and you’ll see the comparison of pitch from one to the other.

However, the difference between stucco and offset is more accentuated in dark colors because they have a greater pigmentation. The more color, the more likely to look different. This doesn’t happen that much with light colors, because they have a higher percentage of white ink, which is colorless.

You have to keep in mind what color you are printing. If you print on kraft cardboard (brown), the ink will it will soak in it and its color will change. But this has a solution. You can print a reserve of white ink (although it depends on the material it will take several past) that will act as the printer’s color base.

Ask for a printed color test

If you already have all the elements well studied and a design that you like, you should always ask for a color test. These tests are done on the material where you are going to print. Although it usually has to be done pre-press and that extends the delivery time a little, it’s the best way to make sure that everything will be perfect, and not get unwanted surprises to the time to receive the final product.