We all worry about our package reaching its destination in perfect conditions. This is why we need to choose the corrugated cardboard box we need and know what types are available depending on the channels or flutes. And we can’t just choose any, for it also affects the postage rates, so the right choice will ensure the protection of the product and the favourable profit.

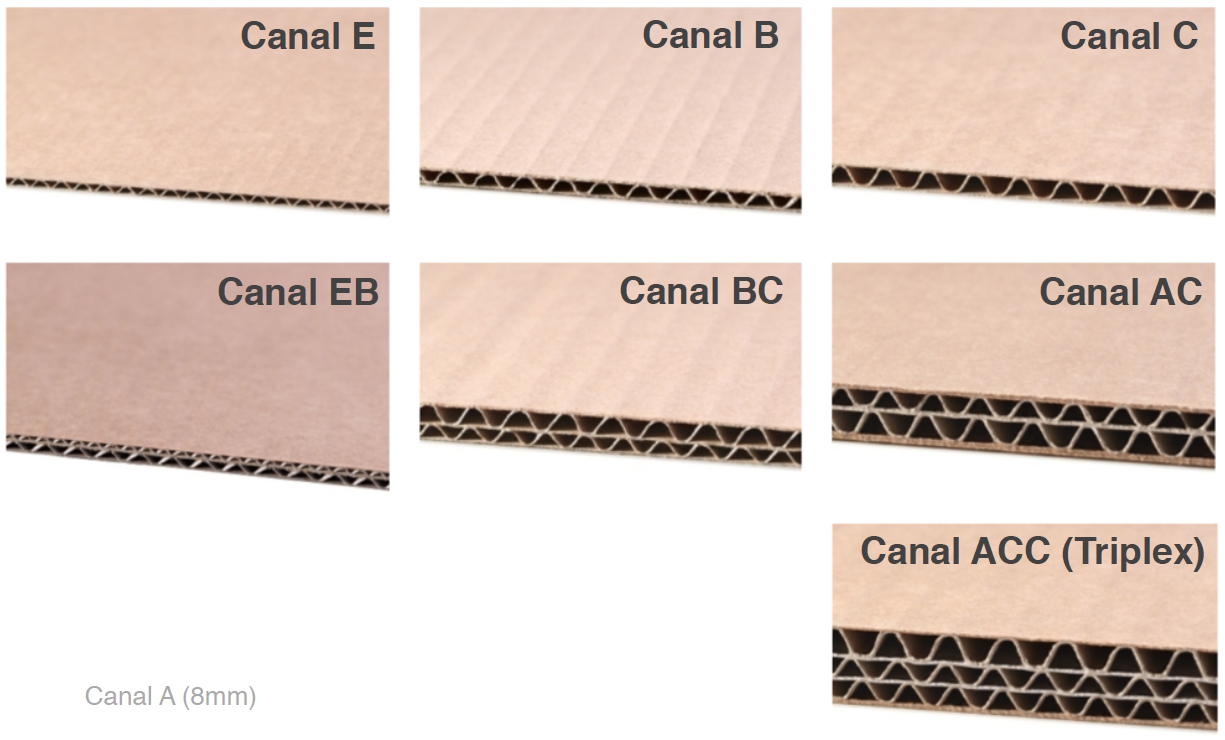

As we have mentioned, the choice of boxes depends on the flute type and size, also known as “profiles”, and they can be told apart by a lettering code.

Cardboard profiles

A flute: the thickest of all, it is perfect to protect the product from impact because of the space between the flutes. However, the surface is not as smooth as others, so we don’t recommend it for complex prints.

C flute: the most common of corrugated boxes, and the RSC (Regular Slotted Containers) standard. It is perfect to pile up, sturdy and resistant to breakage.

B flute: it is the most common for postage boxes. The short flutes make it easy to print on and the durability is average. Also, it is hard and resistant to perforation which means it doesn’t break easily.

D flute: this kind depends on certain manufacturers who give it their own specifications, so it is not a standard in the industry. It is somewhat thinner than types C and B but has a smooth printing surface.

E flute: the best for printing. It is also very resistant to breakage but not as good to avoid perforations, so it isn’t advisable for postage or hard, large or heavy products.

F flute: also known as “microchannel” has 30% more channels per foot. It is half as hard as E, but denser, so both E and F are used interchangeably.

What else must be taken into account?

Usually, boxes are made out of a single corrugated layer, but more can be added so the walls are double or even triple. That way, we achieve greater protection for the product inside. The options are open, so you can adapt the packaging to your needs. If you have questions about restrictions or how they have been tested, just turn the box around and take a look at the manufacturers certificate.

Quality difference

|

Quality |

Type of channel | Approximate thickness |

Weight |

Colours |

|

1 layer (micro plus) |

E | 1.5 mm | 360-370 g/m2 | Brown and white |

|

1 layer (3mm plus) |

B | 3 mm | 405 g/m2 |

Brown and white |

|

1 layer (5mm) |

C | 4.5 mm | 370 g/m2 |

Brown |

| 1 layer (5mm plus) | C | 4.5 mm | 445-495 g/m2 |

Brown and white |

|

2 layers |

BC |

6.5 mm |

605 g/m2 |

Brown |

| 2 layers (plus) | BC | 6.5 mm | 800-818 g/m2 |

Brown and white |

At SelfPackaging, due to the wide range of available products, we use all kinds of channelling. For moving boxes, we use C channel cardboard. We use E channel for postage. And in order to create the right volume, we combine channellings for our cardboard figures, using BC for example.

C flute

B flute

E flute

BC flute

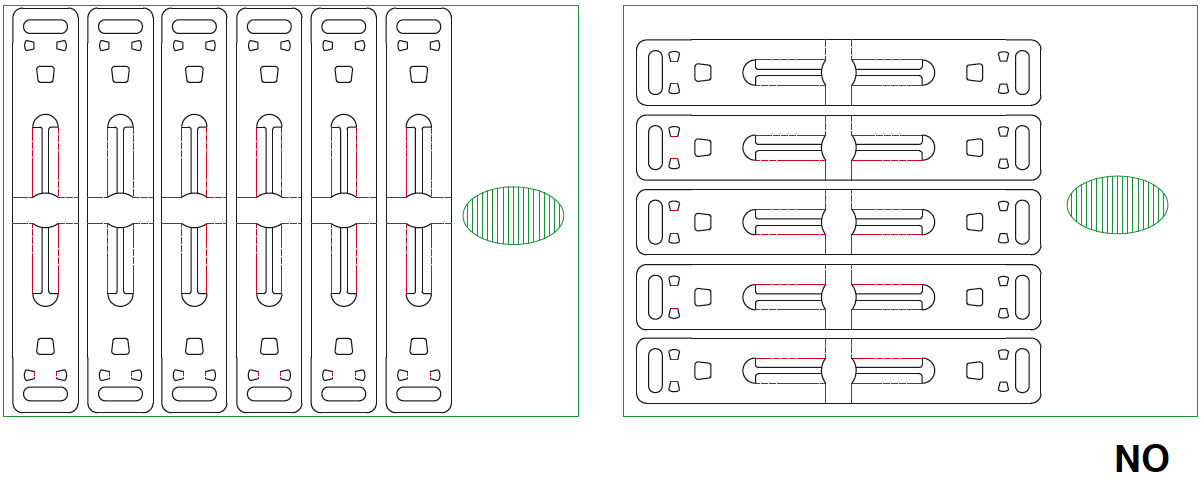

Direction of the channel

In addition to all of the above, the direction of the channel must also be taken into account, for it can affect resistance, assembly and even price, for it may condition a specific distribution in the plate.

2 Responses to How to choose the best corrugated cardboard